We view environmental protection as an important social mission, and as such, we will promote innovative technologies and sustainable business management to reduce environmental impact and thereby pass down a better global environment to future generations.

Achievement a Low-Carbon Society – CO2 Reduced by 50%

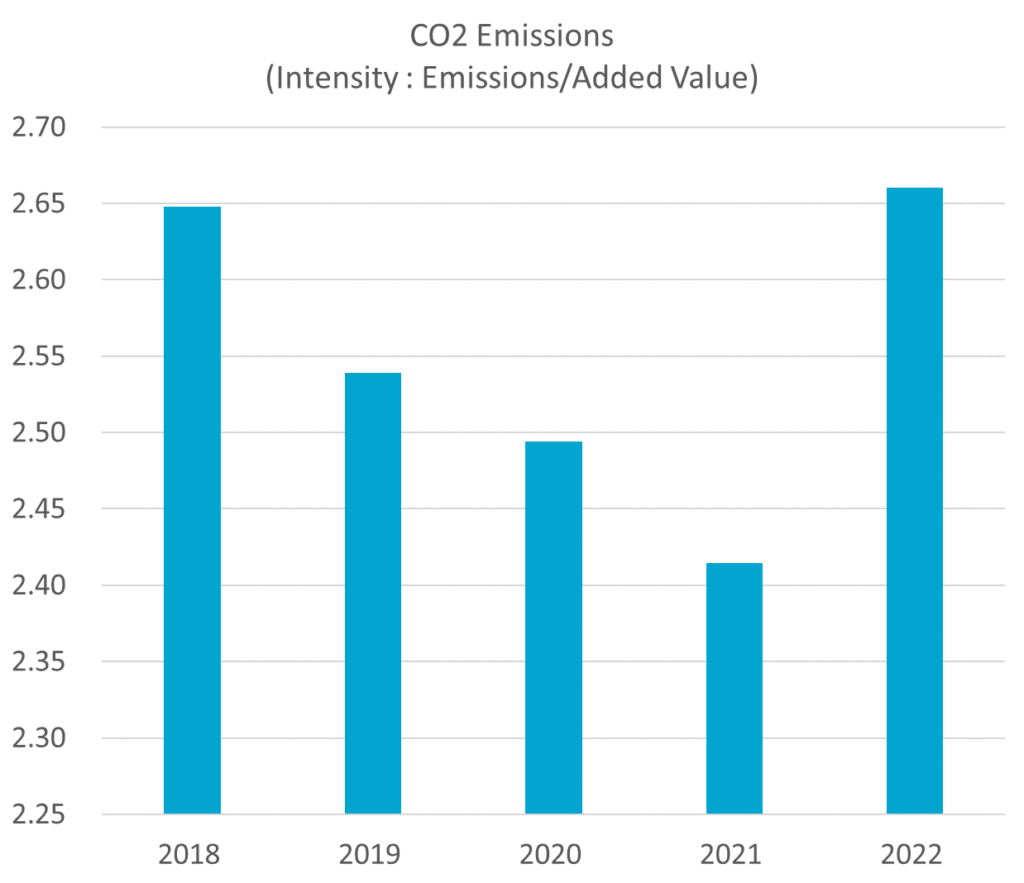

We are working to achieve a low-carbon society and are actively working to reduce our carbon dioxide emissions both through energy conservation and energy creation. Our goal is to reduce carbon dioxide emissions from energy consumption by 50% from the fiscal 2014 level by 2030 (intensity: emissions/value added). In addition, in future investments, we are planning to convert carbon emissions into expenses and factor it in our judgment criteria.

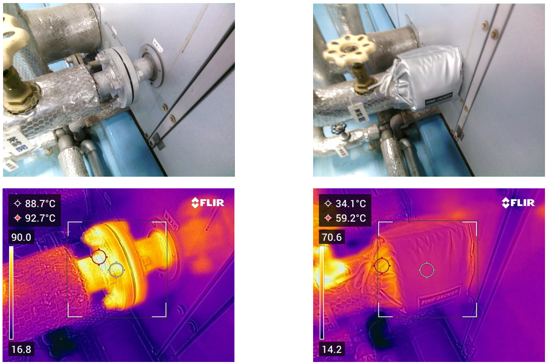

Energy Conservation

We strive to achieve more efficient energy use by introducing equipment and systems to improve energy efficiency and by taking energy conservation into consideration from the product design stage. Reduced energy consumption will lead to reductions in both carbon dioxide emissions and energy costs, enabling us to achieve both environmental protection and economic benefits.

Energy Creation

We have installed a photovoltaic power generation system in the parking lot of our main factory, the Showa Plant, and put it into operation in April 2022. In addition, our proprietary waste liquid combustion boiler uses paint loss, which used to be disposed of, as an efficient fuel and reduces the amount of liquid waste as a result. Natural gas had been used to generate steam, but by using the steam generated by the waste liquid combustion boiler, we have been reducing our consumption of natural gas . We will take advantage of these new energy sources to reduce carbon dioxide emissions.

Achievement of a Recycling-Oriented Society – Waste Reduced by 30%

We are aiming to achieve a circular society by reducing waste generated from all processes by 30% compared to the 2014 fiscal year by 2030 (intensity: emissions/value added). To accomplish this goal, we are actively promoting two approaches: waste prevention and recycling.

Waste Prevention

We strive to minimize waste generation by incorporating innovative product design, implementing process improvements and effective management practices. Additionally, we are dedicated to product designs that allow for lightweighting while maintaining quality, contributing to the reduction of waste generation.

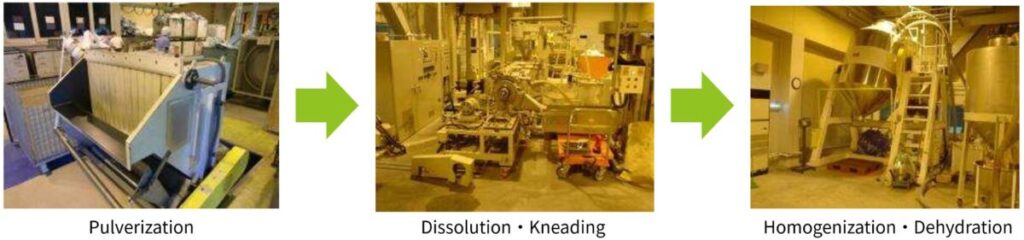

Recycling

Through recycling, we aim to reduce waste by reusing unwanted portions generated during the film manufacturing process as raw materials for creating new products.

Reprocessing construction waste materials into pellets for reuse.

Achieving a Society in Harmony with Nature—Environmentally Hazardous Substances ▲30%

With the aim of reducing the consumption of organic solvents in production processes by 30% from the fiscal 2014 level by 2030 (intensity: emissions/value added) in an effort to achieve a society in harmony with nature, we are working to reduce losses in production and to design products that use smaller amounts of organic solvents.

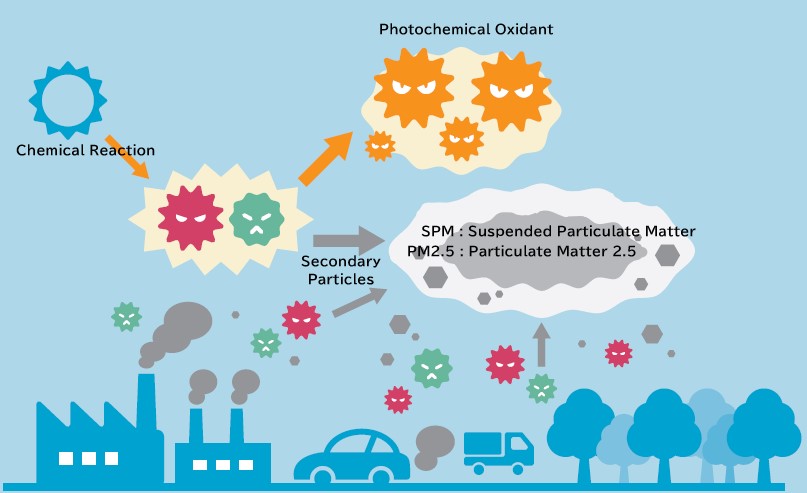

Why are organic solvents bad for the environment?

Organic compounds that easily evaporate (volatilize) and become gases in the atmosphere are collectively called volatile organic compounds (VOCs).

VOCs react chemically in the atmosphere to produce particulate matter and photochemical oxidants that affect the human body, so we need to make efforts to reduce their emissions.

Reducing Consumption

We aim to improve production yields to use organic solvents more efficiently and thereby reduce total consumption. Through our efforts, we will be able to reduce environmentally hazardous substances and make our production process sustainable.

Processing technology and product design that use smaller amounts of organic solvents

We have been working to reduce the use of environmentally hazardous substances by developing designs that enable products to be manufactured with smaller amounts of organic solvents, as well as technologies that enable manufacturing without the use of organic solvents. Furthermore, we are working on the development of an adhesive-free lamination technology, and will apply it to a variety of products.

| 2014 | 2022 results | 2030 target | |

|---|---|---|---|

| Reduction of CO2 emissions | 2.50 | 2.66 (106.6%) | 1.25 (50.0%) |

| Reduction of waste | 0.2138 | 0.3202 (149.8%) | 0.1497 (70.0%) |

| Reduction of the use of organic solvents | 0.4802 | 0.4735 (98.6%) | 0.3361 (70.0%) |

In the 2022 fiscal year, revenue declined greatly due to increase in costs of raw materials and energy, and emission intensity (emissions/value added) increased as a result.

In addition to the in-house measures to conserve and create energy, we are planning to procure renewable energy from outside and utilize non-fossil certificates in order to achieve our carbon dioxide emissions reduction target. In order to achieve our waste reduction target, we are planning to reprocess waste using equipment scheduled to be installed in the 2023 fiscal year and commercialize it as thermally recycled fuel. We have already installed equipment that prevents organic solvents from being released into the atmosphere in the production process. Even so, we will continue promoting our plan to reduce consumption by developing product designs and processes and circulating (reusing) them within the facility.

Response to TCFD Recommendations

The ZACROS Group has formulated the “ZACROS Group Concept” and is committed to “realizing a society that we can be proud of throughout the following generations.” Climate change is a major risk to achieving this goal. The Group will respond to risks posed by climate change, and also actively promote activities, viewing them as opportunities to expand the business that contributes to environmental protection. In accordance with the TCFD recommendations, the Group will disclose information related to climate change and engage in dialogue with investors.

1.Governance

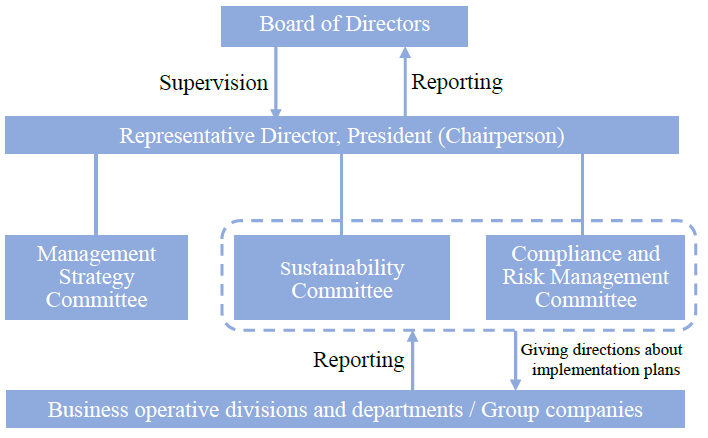

The Group’s Board of Directors recognizes that addressing climate change is one of the most important management issues and oversees the Group’s initiatives to address climate change. Specifically, the Board of Directors, the Management Strategy Committee, and other meeting bodies deliberate on management strategies and plans, taking into account the “risks” and “opportunities” related to climate change issues, and receive reports from each business unit and division as necessary to provide supervision.

In addition, the Group has clearly positioned sustainability as a management issue for the entire Group and established a Sustainability Committee chaired by the Representative Director, President to promote initiatives to address materiality (important issues). The Committee promotes, under the supervision of the Board of Directors, activities related to sustainability, including environmental response (climate change, reduction of environmentally hazardous substances, etc.). The Sustainability Committee reports regularly to the Board of Directors on the status of sustainability and receives its directions and advice.

<Governance Structure>

2.Strategy

Based on the framework of the TCFD recommendations, we have identified the risks and opportunities posed by climate change through 2030. To address higher risks, we have conducted our analysis under a 2°C scenario for transition risks and a 4°C scenario for physical risks.

Financial impact and countermeasures assuming 2030 * (The evaluation of financial impact is based on the Company on a non-consolidated basis.)

| Risks | Details | Financial impact | Countermeasures (initiatives) | |

|---|---|---|---|---|

| Transition risks (2°C scenario) | Policy and Legal | Increase in capital investment and other response costs related to decarbonization measures | Large | • We aim to reduce CO2 emissions intensity by 50%* by 2030 (compared with 2014). * Intensity: CO2 emissions/value added • With regard to energy use, we plan to promote the shift to clean energy such as renewable energy and low-carbon raw materials and fuels, as well as to improve production efficiency through the introduction of energy-saving equipment and other measures. • We will promote the use of alternative materials such as biomass-derived and recycled materials that are not affected by carbon taxes and export restrictions, while seeking to reduce raw material costs. |

| Increase in raw material purchasing costs due to inflated raw material prices resulting from introduction of a carbon tax and export restrictions | Large | |||

| ncrease in raw material costs due to use of alternative materials (e.g., recycled plastic) | Large | |||

| Increase in tax burden due to introduction of carbon tax | Large | |||

| Increase in energy costs (e.g., electricity) | Medium | |||

| Increase in costs for purchasing clean energy (electricity, gas, etc.) | Small | |||

| Increase in transportation costs | Large | |||

| Technology | Increase in costs for developing recycled products | Medium | • We will promote recycled product development based on market trends and strive to effectively recover development costs. • While recovery and maintenance will incur costs, we will manage them in detail and mitigate risks to our revenues. | |

| Increase in collection and maintenance (refurbishment) costs | Large | |||

| Market | Loss of sales opportunities due to delays in the development of environmentally friendly products/low carbon emission products | ※ | • We will actively develop environmentally friendly products (mono-material products, storage battery-related products, zero-energy home/building-related products, etc.). | |

| Decrease in revenue due to shrinking market for products using petroleum-derived materials | ー | • We do not anticipate this to be a risk in the short term, but we recognize it as a medium- to long-term risk and will closely monitor market trends. | ||

| Reputation | Decrease in sales, divestment, and stock price decline due to reputation damage from delays in responding to climate change | ※ | • We will disclose information in a timely and appropriate manner while enhancing communication with shareholders and investors regarding climate change. | |

| Physical risks (4°C scenario) | Acute | Damage to bases, employees, etc., shutdowns, reduced production, increased facility restoration costs, etc., due to natural disasters | Small | • We will formulate BCPs, obtain insurance, and thoroughly manage risk while keeping a detailed track of the physical risks of extreme weather at each of our locations. We will also promote multiple and decentralized raw material procurement bases. |

| Raw material supply disruptions and revenue declines due to supply chain disruptions | Small | |||

| Chronic | Deterioration in employee productivity and increase in cooling costs due to rising average temperatures | Small | • We will utilize digital technology to create an efficient working environment and enhance employee health care and other services. | |

| Opportunities | Details | Financial impact | Countermeasures (initiatives) | |

|---|---|---|---|---|

| Opportunities | Resource efficiency | Reduction of energy consumption and manufacturing costs through the introduction of automated equipment and energy-efficient production facilities | Medium | • We will seek to improve our profitability by increasing the efficiency of our manufacturing and transportation to achieve our CO2 reduction target by 2030. |

| Improved logistics efficiency and cost reductions through higher loading rates and conversion to rail, ship, and electric vehicles as a means of export | Medium | • In transportation, we will reduce CO2 emissions and transportation costs by shifting to more environmentally friendly means of transportation and improving loading rates. | ||

| Cost reductions through energy-efficient process design, including lean and single process design | Medium | • We will promote single-processing and other measures to increase production efficiency, aiming for an energy-saving and low-cost production system. | ||

| Sales expansion and manufacturing cost reductions of recycled products through enhancement of the product lineup with a single material | Medium | • We will effectively reduce costs by focusing on the development of mono-material products and designing products with low waste and high recycling efficiency. | ||

| Energy sources | Reduction of carbon tax burden by addressing decarbonization measures, use of public incentives | Medium | • We will find benefits to our business from the reduction of the carbon tax burden by promoting CO2 reductions, as well as by actively utilizing public incentives. | |

| Improve corporate image through energy conservation activities, procurement of low-cost, high-quality renewable energy and hydrogen, and enhancement of recycling activities | Medium | • We aim to improve our sales by actively working to reduce CO2 emissions, thereby enhancing our corporate image and making our customers more likely to choose us as a business partner. | ||

| Products and Services | Capturing business and increasing sales by offering products that help customers reduce CO2 emissions from their products | Large | • We aim to improve profitability by aggressively developing environmentally friendly products, for which needs are increasing. Mono-material products, recycled products https://www.zacrosameri ca.com/sustainability/ Storage battery-related products for EVs, renewable energy, etc. https://www.zacros.co.jp/ en/product/zef/ Air conditioning-related products for zero-energy homes/buildings Sales of next-generation solar power generation systems • We have also begun to consider products and businesses that contribute to carbon negatives, such as CO2 absorption and fixation, with the aim of gaining a competitive advantage in the future. | |

| Markets | New market development through low-carbon and renewable products and services, as well as increased market entry opportunities due to the growing need for decarbonization in emerging economies | ※ | • We aim to expand our earnings on a global scale by making a series of forays into regions, especially emerging countries, where the need for decarbonization is expected to grow in the future. | |

| Resilience | Expansion of businesses related to heat control, expansion of businesses related to infectious disease control, expansion of businesses related to water and food supply, and growing needs for disaster-resistant housing | Large | • We aim to expand sales of products related to heat and infectious disease control, water and food supply, and disaster preparedness. – Heat management products – Thermally efficient building material products – Material products for pharmaceutical manufacturing – Cell culture technology products – Membrane products effective for disaster preparedness | |

| Expansion of applications and sales of related products (impervious sheets, membrane products, EC products, etc.) in response to increased demand for disaster countermeasure products | Medium | |||

3.Risk Management

The Sustainability Committee takes the lead in analyzing, identifying, and assessing climate-related risks. Specifically, the Sustainability Promotion Manager, who is appointed as the chair of the Sustainability Committee, analyzes, evaluates, and identifies climate change-related risks through the Sustainability Promotion Committee members, who are the heads of each department, and oversees the implementation of the responses and reports to the Sustainability Committee. The Sustainability Committee is chaired by the Representative Director, President, and as appropriate and necessary, gives instructions and reports on countermeasures to business units with respect to reported climate change-related risks.

The Group’s Compliance and Risk Management Committee oversees and promotes risk management for the entire Group, quantitatively identifying and addressing various risks. Both the Sustainability Committee and the Compliance and Risk Management Committee are chaired by the Representative Director, President and they work together to address climate-related risks.

4.Indicators and Targets

The Group’s CO2 emissions targets are as follows.

FY2030: Reduce CO2 emissions (Scopes 1 and 2) by 50% or more compared with FY2014 (intensity: emissions/value added)

FY2050: Carbon neutral (Scopes 1 and 2)

The Group believes that in addition to reducing CO2 emissions from its business activities, it is important to develop technologies and promote businesses that contribute to the reduction of CO2 emissions in society, and the entire Group will work to combat climate change.

<CO2 Emissions Trends and CO2 Emissions Reduction Measures>

The Company has installed solar panel power generation systems in the parking lot and other areas of the Showa Plant (Showa-mura, Gunma Prefecture), the main plant of the Electronics Materials & IT Solutions Head Office, and they began operation on April 1, 2022. We will continue to implement measures to reduce CO2 emissions by installing solar panels and energy-saving systems at our plants.